Your partner in high-quality aluminum casting

Vostermans Alu Foundries has been producing high-quality aluminum casting since 1965 and specializes in casting and processing products for a large variety of applications. In this process, we are committed to creating reliable, long-term partnerships with our customers.

Expect full support: from design to delivery

Thanks to our years of experience and specialist knowledge, we’re able to combine the old craft of aluminum casting with state-of-the-art and efficient casting techniques. We offer customers the opportunity to take the entire process off their hands. This way, we keep full control over the costs and unburden our customers.

- Design

- Prototyping

- Choice of casting technique

- Creation of tools

- Producibility

- Finishes

- Logistics solutions

Our casting techniques

Three casting techniques under one roof

Aluminum Sand Casting

Sand casting is highly suitable for single pieces and small batch production. With aluminum sand casting, highly complicated casting can be produced in an extremely efficient manner.

Solutions for sand casting

Aluminum Gravity Die Casting

Gravity die casting is the perfect choice for applications that require a solution that’s somewhere in between sand casting and high-pressure die casting. Aluminum gravity die casting requires lower investment costs than high pressure die casting, and is more durable than sand casting thanks to the usage of a steel die.

Solutions for Gravity Die Casting

Aluminum High-pressure Die Casting

High pressure die casting is extremely suitable for casting requiring high dimensional accuracy and for producing large batches.

Solutions for High-pressure Die Casting

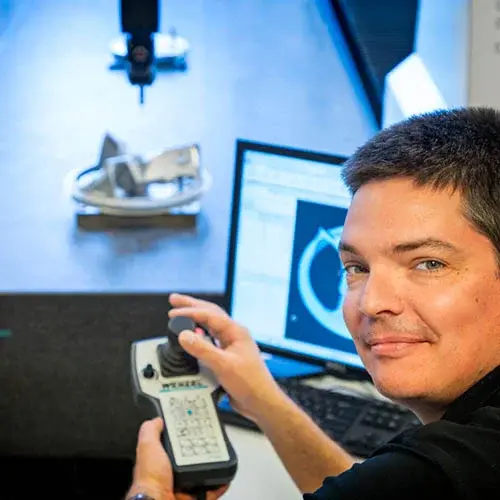

Quality and Environment

Quality requirements for aluminum casting are becoming increasingly more strict. We are continuously working on meeting these standards and strive to deliver the highest possible quality. We also feel responsible for contributing to our environment in the right way.

From prototype to large batches

Sand casting in particular is ideally suitable for producing high-quality prototypes at relatively low investment costs. Thanks to 3D sand printing techniques, it is possible to cast a fully-fledged prototype in an even shorter lead time and at even more affordable prices.

Receive insights in your mailbox

/VAF/Landscape/Vostermans%20Alu%20Foundries%20Gravity%20Aluminium%20Casting%20L.jpg)